R&D [Research and Development Area]

Inkjet Paper/Imaging Materials

Inkjet Paper

Beyond Photo Inkjet Paper

As a leading company in photo inkjet paper, we have developed well over 100 types of inkjet paper for photos, labels, etc. These products are used by everyone as inkjet photo paper wrapped in colorful packages that are lined up in mass retailers.

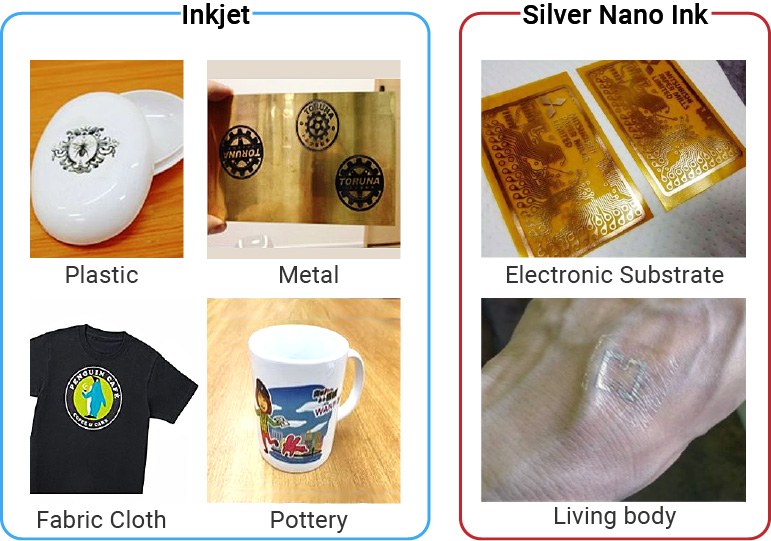

The range of applications of inkjet technology has expanded greatly from the basic function of outputting images to include printing electronic circuits, printing display components, applications in 3D printers, and cell printing.

This is because it is an environmentally friendly and modern technology that applies what is needed only where it is needed.

Our company always considers the protection of resources and the environment, and continues to research and develop inkjet paper that goes even further.

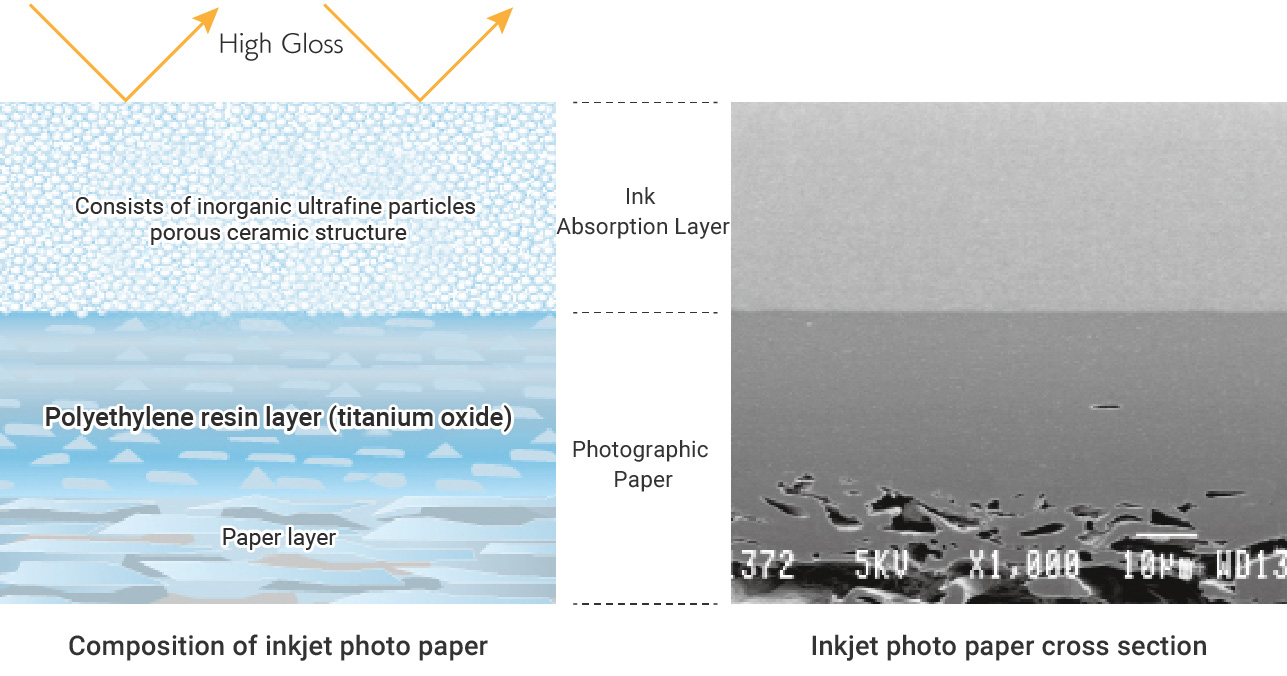

Porosity and light control as the basics

Inkjet paper is made by applying an ink-absorbing layer to paper, RC paper or film. The ink absorption layer instantly and accurately absorbs the countless picolitres of ink droplets fired by the printer head, and fixes them firmly in place. Although it seems there are no holes on the surface of inkjet paper, there is a sponge-like porous structure with countless holes that are tens of thousands of a millimetre apart, far less than the size of a virus.

In addition, it has transparency because of its inorganic ultrafine particles of about 10 nm, which are much smaller than the wavelength of light, allowing the beautiful colors of the ink to be reproduced accurately.

Some of the highest grade photographic inkjet papers have an extremely high gloss that other grades of paper do not have. This high gloss is achieved by using our proprietary ultra-precise multi-layer coating technology to create a one-of-a-kind "optical thin film" on the surface and control the light reflectivity. Inkjet paper is thereby made up of various technologies including for dispersal of inorganic particles, binding, fixing dyes and pigments contained in the ink, creating satisfying surfaces, ink absorption control, ink fade prevention, control of light reflectance, and more.

New Inkjet Paper

In order to aim even further, we are developing new inkjet paper from a variety of perspectives, including customer requests, resource conservation, environmental protection, and safety and security.

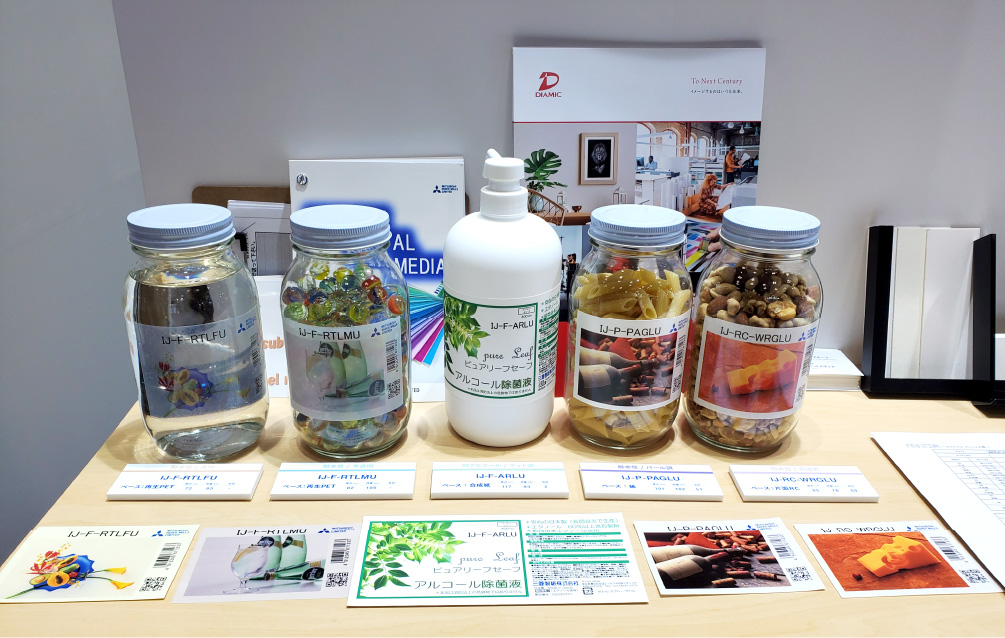

One example is inkjet paper for labels. The label market is expected to have a high growth rate for a variety of applications, including food and medical applications. In this situation, inkjet labels are expected to grow in the future, as there is a trend toward small lots and a wide variety of products, as well as a trend toward greater efficiency. Utilizing the technology we have cultivated over the years for photographic inkjet paper, we offer products with various textures (glossy, matte, etc.) and base materials (paper, PP, PET, etc.). We have a lineup of products that have qualities such as durability and alcohol resistance, allowing you to select the product that is suitable for your application. Our product line is also environmentally friendly, including the use of recycled PET products and water-resistant paper base materials.

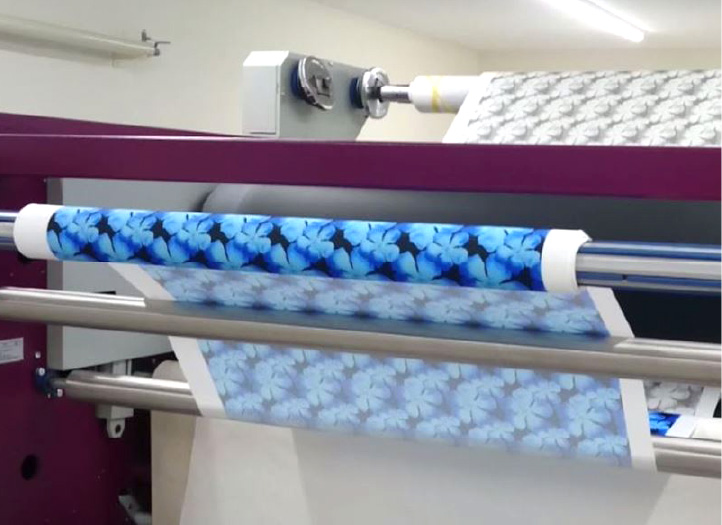

Application of Porous Technology

The technology to create porosity, which is the basis of inkjet paper, is not limited to printing images, but is also applied to dyeing, which creates patterns on fabric, and printed electronics, which creates electronic circuits through printing. This is due to the porous nature of the paper being highly compatible not only with dye inks and pigment inks that create images, but also with sublimation inks used in dyeing and silver nano inks used in printed electronics.

Sublimation transfer paper is an inkjet paper specialized for sublimation ink. By applying porous properties, the drying time after printing sublimation ink can be significantly shortened, greatly improving the productivity of fabrics. The design can be transferred by printing on sublimation transfer paper, layering it on polyester cloth or other fabric, and applying heat and pressure. It is widely used in the manufacture of ties, various tops and bottoms, sports apparel, uniforms, etc.

Transfer inkjet paper is new for the applications in printed electronics to transfer circuits made with silver nano-ink. On top of the porous material, a very thin layer of several 100 nm is formed that easily peels off. It is anticipated that it will be used for prototyping and education. Porous materials not only have the property of absorbing, but also have functions such as retaining, releasing, having continuous pores, having nanoscale pores, and controlling light transparency. We will continue to develop unprecedented products that utilize these functions.

Imaging Materials

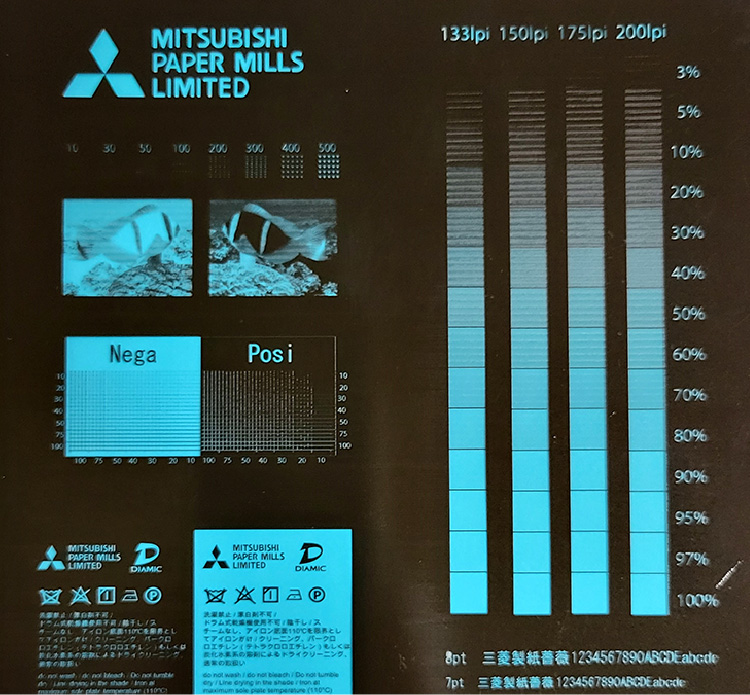

Silver Halide Thermal Film

By combining the silver salt material technology and heat-sensitive material technology cultivated through photographic paper, silver salt printing plates, and thermal recording paper, we are developing a completely process-free silver salt heat-sensitive film that does not require any chemical development. Conventional silver halide films for graphic arts require a wet processing process with a developer to obtain a blackened image, but with this technology, it is possible to form a metallic silver image with high optical density even in the UV range on the spot by simply applying thermal energy.

The thermal laser platemaking film “TRF-IR830” is compatible with laser drawing and achieves high resolution, making it possible to create even higher quality screen printing plates and flexographic printing plates. Unlike conventional burn-off type laser drawing films, it does not generate dust, and combined with the process-less feature, it is an environmentally friendly film.