R&D [Research and Development Area]

Paper and Pulp Related

There are a wide variety of paper products around us for the purpose of using the three major functions of paper: recording, wrapping, and wiping. In general, paper is composed of pulp fibers derived from trees, inorganic substances, and other additives. In order to realize a sustainable society, we are committed to the restoration of forest resources. The pulp fiber used in our products is made from FSC® certified wood, recycled resources, and other controlled raw materials. All of the Mitsubishi Paper Mills Group's production facilities are CoC certified.

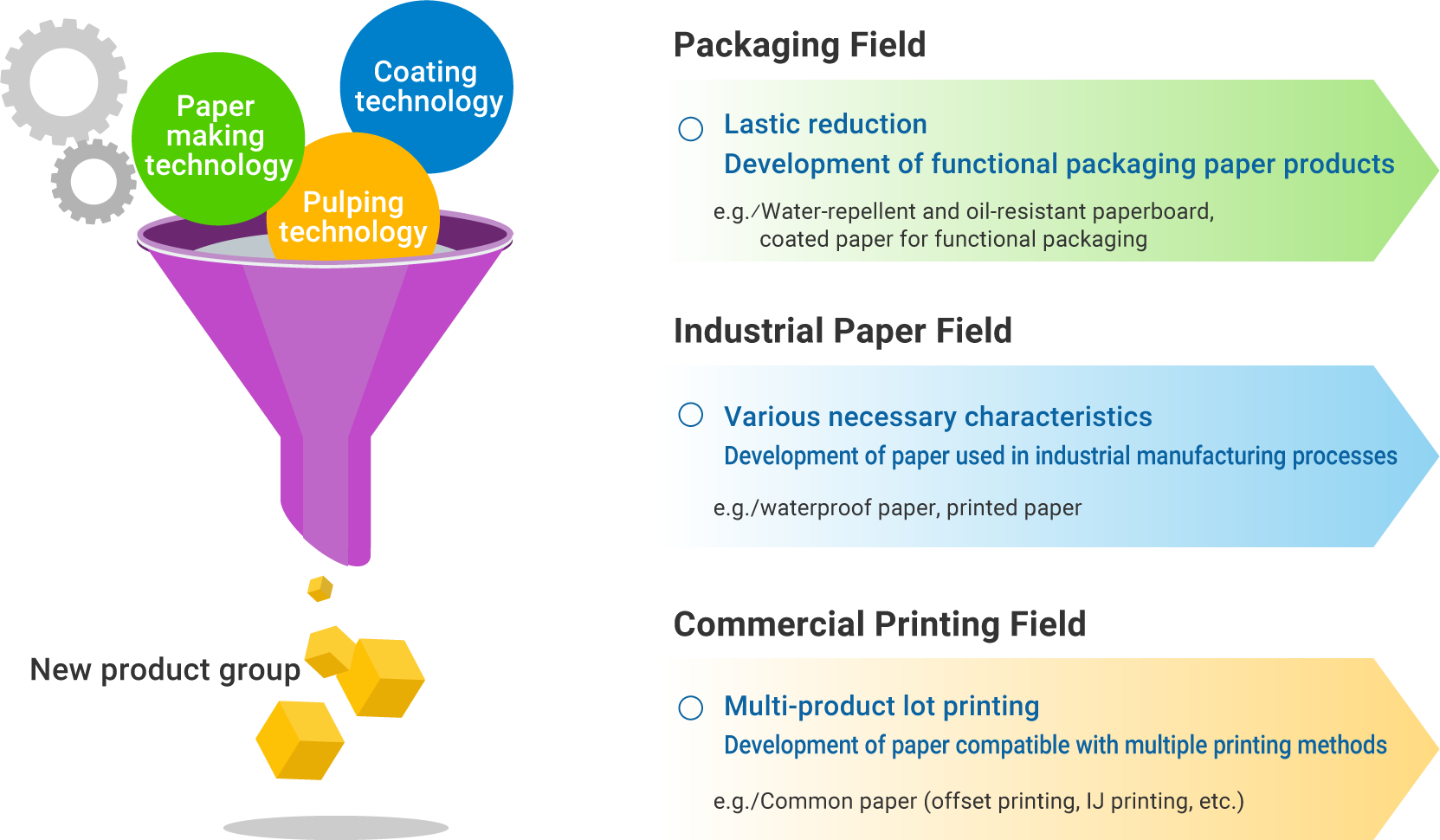

From pulp to paper, future product lines

- To make paper, wood chips are first converted into pulp in the pulping process. Using the pulp as the main raw material, paper products are made through processes such as papermaking, coating, and converting.

- We are one of the few mills in the industry with integrated production from pulp to paper, and we are working to improve and develop the raw material pulping process, which has a significant impact on paper quality.

- In addition, using the coating technology cultivated through the production of printing and information paper, we are developing paper products that can be used not only as "information recording media" but also in a variety of other fields.

- We are also developing coated paper for functional packaging by applying various compounding designs and water-based coating technologies to kraft paper, which was developed based on our pulp production know-how. We are also expanding our lineup of water-repellent and oil-resistant paperboard and sanitary paper as paper products more closely related to daily life.

- We will continue to develop high-quality, highly functional products that meet the needs of the times by leveraging our accumulated expertise in the integrated production of paper products.